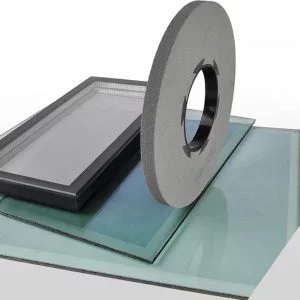

Low-E Glass Edge Deletion Wheel

Low-E or low emissivity glass edge deletion wheel is a tool built to process and remove the coating of glass surfaces in a glass edge. This wheel is designed with metal particles, which are deposited on the glass surface with a vacuum.

This tool is ideal for de-coating Low-E Glass materials, including wet and dry grinding. It’s commonly used for homes and commercial buildings because of its insulating properties–the Low-E glass edge deletion wheel features a coating glass that offers a lower solar factor than a standard coated glass. It comes with a control sensitivity, which implies that it won’t shake while in use.

Moreover, it’s a tool characterized by high precision. With this, there won’t be any need to use another solvent to clean it after removing the coating– this leads to a glossy finish glass surface.

Important Features

- High-quality system components for maximum efficiency

- Easy to use and suitable for different kinds of glass plate coatings

- Easy to Integrate

- Much easy to maintain and has a longer lifespan

- Light and easy to carry around

Detailed Description

Low-E Glass Edge Deletion wheel is trendy and important in architectural and building industries. This is because of its energy-saving eco-friendly features. As a high-quality and decoating wheel, it is highly efficient for cutting, automatic decoating, or removing glass coating. Besides, it also features a strong cutting mechanism, a well-distributed air hole, wide adjustability, and a special polyurethane bond.

Specifications of Low-E Glass Edge Deletion Wheels

Some popular specifications of the Low-E deletion wheel that you can see in the market are in the table below:

|

Low-E Glass Edge Deletion Wheels Specification Chart |

|||||

| Outer Diameter | Thickness | Inner Diameter | Bonding Agent | Shape | Suited For |

| 200 mm | 30 mm, 26 mm, 20 mm, 17 mm, 15 mm, 14 mm, 13 mm, 12 mm, 10 mm, 8 mm | 76.2 mm | Rubber | Flat | safety glass, tempered glass, architectural glass, frosted glass, patterned glass, insulated glass, laminated glass, glass brick, optical glass, auto glass, and solar glass

|

| 100 mm | 20 mm, 15 mm, 12 mm, 12 mm, 10 mm, 8 mm | 20 mm | |||

| 70 mm | 15 mm | 8 mm | |||

| 60 mm | 15 mm | 8 mm | |||

| 50 mm | 12 mm | 16 mm | |||

Applications of Low-E Glass Edge Deletion Wheel

- For removing the metal film of the Low-E glass edge for further processing

- As a coating removal machine, for cleaning the edge of Low-E glass and glossy finished.

Benefits of Edge Deletion Wheel

A glass deletion wheel or a Low-E deletion wheel is beneficial in different ways. As an important tool in glass processing, decoating, and polishing, it is used mainly to remove Low-E coatings on glass. Also, it’s ideal for deleting tough-to-remove coatings with no marks on the glass. It can be seen in different sizes, particularly for automatic or semiautomatic edge deletion machines and portable handheld edge removal tools.

The tool is seen as a top-of-board wheel in the market because of its high-efficient performance in glass coating removal. The following are some benefits of the Low-E Glass Edge Deletion Wheel.

- Convenient and easy glass decoating process

- Help remove the metal coatings from Low-E coated glass

- Ideal for edge deletion process on Low-E glass

- Makes an immense contribution in n the adhesion part of the space bar

- Offers any glass type (patterned glass safety glass, etc.) glossy surface finish.

The Process of Low-E Glass Edge Deletion Wheel

The process of removing narrow strips of coating around the edge or perimeter of the size of the glass is referred to as edge deletion. This process is used in the production of laminated glass or insulated glass units. To strip or remove a soft coat, an edge deletion wheel is used.

To strip the glass, the wheel will run across the glass jumbo on a CNC-controlled bridge. The grinding head motor will spin the wheel and push it against the surface, using a bar of pressure that ranges from 1 to 3 at a speed of around 2000 rpm. This will remove the coating when the cutting head moves across the glass surface in a pre-programmed pattern.

There are three crucial points when using the edge deletion wheel. These include the grinding head pressure, wheel rotational speed, and traverse speed.

Low-E Glass Edge Deletion Wheel Partner Tools and Machines

To make the deletion process faster, more quality, and more efficient, the Low-E glass edge deletion wheel will be used with some machines and tools. These tools and machines include:

- Portable Low-E Glass Coating Edge Deletion Handheld Tools

Low-E glass edge deletion wheel and Low-E glass edge deletion handheld tool can be great partners. The tool is characteristically light and portable, and electricity or pneumatic can be used to power it on. The diameter of its decoating wheels starts from 58 mm, 100mm, to 200 mm.

- Semi-Automatic Glass Coating Low-E Edge Decoating Machines

Using the Low-E deletion wheel, the machine will ensure the decoating process is very easy. The machine can be a semi-automatic operation machine featuring one-to-two-wheel spindles. It is convenient due to its glass or the decoating spindle that moves during the deletion process.

Why is Glass Edge Deletion Wheel Necessary?

The glass edge deletion wheel is eco-friendly and energy-saving. With this, it is highly recognized in the architectural and building industries. Since the coating is a delicate thin film depositing on the glass surface, Low-E glass is usually insulated with another piece of glass.

Low-E coating faces the inner side of double glazing from time to time. The space can be filled up with inert gas or can be ordinary dry air. Inert gas or dry air does not corrode the Low-E coating, making the coating corrosion-resistant.

A spacer bar always separates the spacer between two pieces of glass. These bars may include reinforced plastic, rubber, stainless steel, or aluminum steel. Butyl is preferred to be the adhesive to seal between glass and spacer bar because of its excellent moisture-proof. Nonetheless, the adhesion between Low-E coating and butyl doesn’t perform well, which makes removing the Low-E coating around the edges of the glass necessary. This is a process called Low-E deletion. After deleting Low-E edges, the glass edges become exposed. Butyl and the glass get in direct contact, which ensures the best performance of the adhesion.

Final Note

The Low-E glass edge deletion wheel is the next-generation tool for glass coating removal, polishing, and glass processing. It features an outstanding cutting quality which makes getting a glossy surface finish in no time highly possible. Work is made sufficient and efficient because of its integrated grinding unit, which has an automatic speed adaptation.

As a modern glass edge deletion wheel, it will help keep the glass in great condition. So, investing in this product is never a waste. Besides, buyers are guaranteed a longer lifespan and durable service for your glass work.

More Customized Polishing Wheels are available, contact us.