Diamond Honing Tools for Expert Bore Finishing

Diamond honing tools help with a precision surface. They feature abrasive grains joined together with a bond. The shapes of these grains are uneven. Abrasive grains come in a different size range of 300 to 1500 mesh grit (between 10 and 50 micrometers in diameter). The smaller the grain sizes, the smoother the work piece surface will be

Diamond honing tools for bore finishing can handle operating pressure and surface speeds even if they are higher, which makes them different from their traditional counterparts.

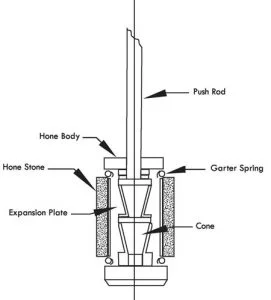

The work of diamond honing is to transfer to a work piece the power generated by the device. It precisely helps improve the size, straightness, tapers, and finish of a specific bore. The tool features the honed body, a driving shaft, and a spindle nose adaptor.

With hones and honing tools, several industries can effectively polish the finish of both the exterior surfaces and internal bores.

Diamond honing tools are in three fundamental types, including hand hones, flexible hones, and honing sticks/tools.

These honing tools are considered better than standard vitrified abrasives when it comes to honing ceramics or tungsten carbide. This is because diamond honing tools are significantly stronger for such hard materials. In addition, diamond hones could be a way to save money on honing because they are impressively cost-effective.

Important Features

- Made from quality materials that offer high performance

- Work with diameters that range from 1.52-1524mm (.060- 60 inches)

- Eco-friendly and cost-effective

- Make a wide range of finishing operations more efficient

- Very strong and durable with quicker action when compared to other abrasive products.

Detailed Description

Honing means to sharpen with a hone or whetstone. It’s a process that is carried out on the sharp edge without affecting the alignment of the cutting machine’s knife.

Moreover, honing gives the final size and develops the needed finish pattern on the inside of cylinder or tubing bores.

For finishing, the abrasive stones with the proper grit and grade are rubbed against the surface of the work piece. The stones rotate and reciprocate in the section with hone abrasive under regulated pressure. The surface of the honed portion features a cross-hatch pattern made through rotation and reciprocation.

Diamond Honing Tools and Their Parts

Diamond honing tools are designed to transfer to a work piece the power they generate. With honing, the size, taper, straightness, and finish of a bore can be improved. However, honing does not often fix axial alignment/placement.

The honing tool comes with a driving shaft, a spindle nose adaptor, and a honed body. The honed body features a cone that is linked to a push rod. The pushrod is moved up and down in the honing body by a motor or hydraulic cylinder within the driving shaft. The actuator is at the head. The expansion plates move outward to enlarge the stones as the cone descends.

Abrasives stones are used to remove the stock material from the work piece. The stones are retained in place in the diamond honing tool by the garter springs, and when the tool is withdrawn from the bore, the garter springs collapse them.

Hone Guides for Diamond Honing tool

Hone guides for diamond honing tools help protect the hone stones by stopping the metal of the tool from hitting the surface of the bore during entry and exit.

Bushing of Hone Guide

The primary purpose of the bushing of hone guide is to properly direct the honing tool into the center of the bore. The bushing is typically made of hardened carbide or steel.

(Parts of Honing machine associated with diamond honing tools)

Adjustable Cone

With an adjustable cone, the bottom of the stones can be extended to account for wear and retain the size of the bottom during blind bore honing.

Diamond Honing Tools and Their Manufacturing Process

What is seen to be and used as the honing tool is a diamond abrasive boring bar, designed with an extensible soft cast iron sleeve covered permanently with 100 or 120 grit natural diamond abrasive, or designed with a sintered sleeve with the incorporation of abrasive.

Types of Bonds for Diamond Honing Tools

There are different types of bonds used to determine the hardness of diamond honing tools. These include:

- Cobalt Iron Bond (M): This is the strongest of all the three basic bonds. It is for tungsten carbide that has a cobalt concentration that is above 25% and great in the honing tools for iron and ceramic glass.

- Bronze Bond(MB): This is a medium bond great on several heat-treated steels more than HRC73. It’s perfect for tungsten carbide and has a cobalt concentration that ranges from 11-25%.

- Resinoid Bond (S4): This is a soft bond for tungsten carbide that has a cobalt percentage above 11% and also for other tough materials.

Types of Diamond Honing Tools

Below are the three types of diamond honing tools with their respective use and properties:

- Flexible Hons: Like other hones and honing tools, these hones are used in smoothing or polishing the finish of exterior or interior surfaces.

- Hand hones: These are otherwise called diamond hones, and they help in sharpening the edges of ground cutting-tool offhand.

- Honing Sticks: Honing sticks/tools help finish internal bores.

Advantages of Honing with Diamond Honing Tools

- Low-priced fixtures or less complicated

- Support both long and short bores

- Keep the original centerline of the bore

- Quite accurate

- Can finish any material, irrespective of its hardness

- A central shaft helps power the hone, which makes bending the shaft not lead to tapered holes.

- No power is required in turning the work piece, and no chucks rotating tables, or faceplates are needed.

Diamond Honing Tool Vs. Diamond Wheel

- There will be a round hole with high/low regions or no taper if the initial processes leave enough stock for the hone to clear out all the imperfections.

- Honing makes use of a big contact at a moderate speed when it’s compared to fine boring or grinding, which uses a small contact at high speed.

- The simultaneous rotating and reciprocating action help form the crosshatched pattern, which is great for retaining lubricant.

- Like diamond wheels, diamond stones can work for honing diameters that range from001 to 0.0001 inch and closer accuracies.

Benefits of Diamond Abrasive

Below are some of the benefits of diamond abrasives for making diamond honing tools:

- It features proper hardness: Graphite, coal, and diamonds have the same chemical elements. Graphite and coal feature carbon atoms organized in sheets, which gives them a velvety feel. As crystalline carbon, diamond contains carbon atoms that are arranged in a tetrahedron. For a 3-dimensional space, every carbon atom is joined to the other five carbon atoms. Graphite and coal have carbon sheets that are not as strong as this. The hardness of diamond honing tools is due to the chemical structure, which can cut through any substance without excluding other diamonds.

- It is durable: The bonds (Resin and metal) in both types of diamond abrasive are ideal because they don’t wear away easily. They go through a gradual process, making the fresh layer of the diamond to polish the concrete. This explains why it’s the bond that makes the tool durable and not the diamond, which wears away from the tool eventually. Due to the hardness of the diamond tools, therefore, they have a longer work life when compared to other abrasives, which makes diamond honing a good option.

- It features speed cutting: Since diamond abrasives are characterized by impressive hardness, they can help grind quicker than other abrasives. Diamond honing tools can easily grind through a hard stone with fast speed instead of grinding repeatedly.

- It is cost-effective: Diamond abrasives are not as expensive as other abrasives, despite their unique characteristics. Also, with diamond honing tools, users can do more work with fewer tool changes due to their endurance.

Final Note

Even though bore finishing is very demanding, diamond honing can make the process impressively easy. Several industries prefer the use of diamond abrasives basically because of their durability and hardness.

The Diamond honing tool is designed to transfer the power of the machine to the work piece. As an efficient process, honing will improve the straightness, size, taper, and finish of the bore.

It features a honed body, a drive shaft, and a spindle nose adapter. Also, the diamond honing tool has three bond types. Any of these bonds can be chosen depending on the nature of the work involved.

More customized diamond tools are available, contact us.