Metal Bond Cutting Wheel

Short Description:

The metal bond cutting wheel is a perfect abrasive tool for cutting. This tool is divided into two types; metal bond diamond cutting wheel and metal bond CBN cutting wheel. The metal bond diamond cutting wheel is a type that focuses on cutting hard materials for wear-resistant and short-chipping processes on various materials like glass, ceramics, carbide, ferrite, quartz, graphite, and semiconductor materials. On the other hand, metal bond CBN cutting wheel is applied on various materials that are mostly composed of affinity for carbon just like the iron-based alloys.

Feature of Metal Bond Diamond and CBN Cutting Wheels

Here are some unique selling features of the metal bond cutting wheel that guides every potential buyer on purchasing the metal bond diamond and CBN cutting wheels.

- High cutting performance. High deep cutting with a longer lifespan.

- Low-cost maintenance and highly durable. This tool doesn’t need a high cost in maintenance because of its durability which offers longer maintenance in terms of wheel sharpness.

- High wear resistance. This tool does not wear out easily even with more production output and it transfers heat much better than other tools.

- Useful on various materials. This tool can be applied to various materials like optical glass, tungsten carbide, steel, ceramic, quartz, titanium alloy, and many more.

The invention of these cutting blades is very essential and important in the history of manufacturing as it helps in keeping precision in cutting. This tool is a very great choice for serving unique applications in various work fields. This high-quality cutting wheel can guarantee a smooth, fast and clean operation for any workpiece.

Metal bond cutting wheels like the diamond and CBN cutting wheels are created for providing the best service and features needed in various applications. Examples of these include construction sites, tool shops, medical manufacturing industries, automotive shops, and many more. When it comes to cutting materials, this tool is highly recommended for its great benefits and advantages. This is also the reason why explaining its types, features, and applications, is important for every potential customer.

Detailed Description of Metal Bond Cutting Wheel

Metal Bond Cutting Wheels

Metal bond cutting wheels are ideal tools for choosing standard wheels that are built for several cutting requirements. This tool ensures excellent performance when it comes to cutting several materials in their highest quality. What makes it highly efficient is its superb form which is 10 times better than polyimide, resin, or conventional bonds.

This type of cutting wheel is suitable for any conditions or application like in wet cutting or dry cutting operations. This tool has its own way of removing boosting materials through releasing heat generated via metalcore and binder. It is also capable of extending enough time between the dressing and truing process.

The metal bond cutting wheel is considered the best precision tool for various materials like glass, quartz, ferrite, and many more when it is applied correctly. Most industrial fields find this tool as the most suitable in molds precision processing with its high blade thickness and accuracy during operation.

Specification of Metal Bond Cutting Wheel

|

|

||

| Hole | Diameter | Thickness |

| 12.7, 19.05, 20, 31.75, 50.8, 60, 127 | 50 – 400 mm | 0.2 -2.0 mm |

Types of Metal Bond Cutting Wheels

Metal bond cutting wheels can be categorized into various types. These include the following:

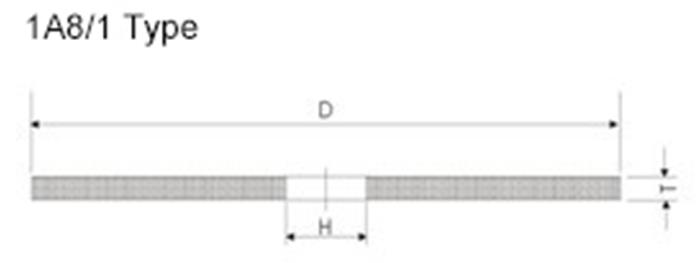

1a8/1: This is a metal bond cutting wheel type without a water slot.

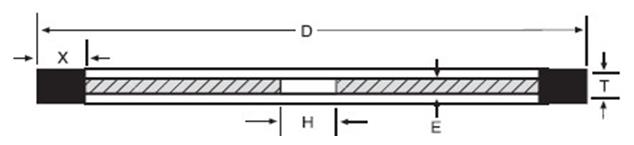

1a8/2: This type is encompassed a water slot.

Other types include:

- 1a1 type: This is a type of metal bond cutting wheel that is known for its thickness in the work layer is quite similar to steel plate. This tool type is very applicable for precise cutting and grooving.

- 1a1r type: This is a type of metal bond cutting wheel that is also popular for its higher thickness in its work layer compared to steel plate materials. This tool type is very helpful in removing chips and the cooling process and can work effectively for grooving and cutting various components.

Features of Metal Bond Cutting Wheels

Here are some features of the metal bond cutting wheel that make it very beneficial and essential for various industries.

-

- High-quality service and efficient tool performance: These cutting wheels are sintered with sternum powder, silver, mill, copper, or cobalt, which contributes a big factor in enhancing the tool’s performance on numerous surfaces. Mainly for semiconductors, ceramics, glass, silicon, refractories, and quartz.

- High-quality tool and durability. This cutting wheel ensures high quality and the longest service life even if there is no maintenance done.

- Flexibility and Compatibility. This tool can easily adapt and adjust to any predetermined alterations to any workpieces. During the adjustment process, the wheels can guarantee lesser quality control issues. When it comes to compatibility, this tool is applicable on numerous materials like a mill, copper, cobalt, sternum powder, or silver, making them ideal for refractories, glass, silicon, ceramics, quartz, semi-conductors, and other surfaces.

- Quality wheel properties. These metal bond cutting wheels offer more retention properties or hardness compared to other types of bonds. Plus, even with the most energetic cut-off applications, the dimensions of the tool do not change.

- Low Heat Generated. Heat degenerates fast through metalcore. This feature makes the tool more suitable and applicable for great material removal rate operation.

Applications of Metal Bond Cutting Wheels

Since metal bond cutting wheels are highly durable and have hard-wearing qualities, various industries are fond of applying these tools especially on the glass, fine ceramics, semi-conductors packaging, hard metal, grinding materials, magnetic materials, electronic components, and other industries.

When it comes to applications, metal bond cutting wheels can be categorized into two: metal bond diamond cutting wheels and metal bond CBN cutting wheels. These two categories are used depending on the specific cutting applications such as deep cutting, glass cutting, wet or dry cutting, cut-off, and many more.

Note: There are several outer diameters for metal bond diamond and CBN cutting wheels specifically 3″, 4″, 5″, 6”, 7″, 8″, 10″, and 12″. The thickness of the wheel may depend on the client’s requirement.

Metal Bond Diamond Cutting Wheels

This type of metal bond cutting wheel is defined as cut-off tools that are used effectively for several materials that are considered as wear-resistant and hard, short-chipping materials like carbides, glass materials, printing circuit board, quartz, gems, magnetic materials, and many more.

Features of Metal Bond Diamond Cutting Wheels

Below are some of the features of metal bond diamond cutting wheels:

- Highly durable: The cutting wheels are highly durable and wear-resistant which can maintain longer service tool life even in the long run. This also enhances productivity in the work process by minimizing the changes and dressing frequency in the wheels.

- Compatibility on different workpieces: This cutting wheel is very compatible for application on various materials like ceramics, glass, quartz, semi-conductors, and other surfaces.

- Transfer heat much better: This tool can perform fast dissipation of heat through a metal core. This makes it very ideal for high material removal rate operations.

Metal Bond CBN Cutting Wheels

Metal bond CBN cutting wheels have unique characteristics in cutting materials. These cutting wheels have carbon affinity which includes iron-based alloys and is known for their effective cutting properties. Unlike other types of cutting wheels, metal bond CBN cutting wheels are applied for cutting various materials with high hardness levels like mold steel, cast iron, bearing steel, tool steel, and other ferrous metal materials.

Features of Metal Bond CBN Cutting wheels

Here are some of the features of metal bond CBN cutting wheels

- Has high sturdy properties for cutting workpiece: Various industries and work fields use this cutting wheel for any related cutting works due to its sharpness in cutting materials where it shows sturdiness and durability in the long run.

- Strong control on abrasive materials: This type of metal bond cutting wheel has high bearing cutting pressure which is the reason why CBN cutting wheels keep the abrasive material in close contact with the workpiece. This also ensures a strong relationship between the abrasive material and the bonding agent.

- Resistance on impacts: This tool is known for its great resistance to impacts during production. This allows the structures to stand up correctly even in interrupted cutting applications.

- Shape quality retention: It maintains the original shape of the tool even with the most energetic cut-off applications.

Summary

Due to the immense development in high-speed cutting technology and cutting precision, the presence of cutting wheels is becoming more and more important. Metal bond cutting wheels are very advantageous due to their suitability in various conditions like wet or drying cutting applications. With this, operators can have a faster and easy cutting process through diamond and CBN metal bond cutting wheels.

These metal bond cutting wheels are considered to be widely-used tools in many production environments and industries because of their incredible features such as their own outstanding performance, high-quality service, retention of original shapes, better wheel retention properties or hardness, impressive compatibility, the long service life of cutting pieces, and other features.

May this guide you vastly and help you make the better choice in purchasing high-quality tools designed to meet your professional needs and requirements for any cutting process.

There are many other cutting wheels that can be customized, feel free to contact us.

More customized specifications are available, contact us.