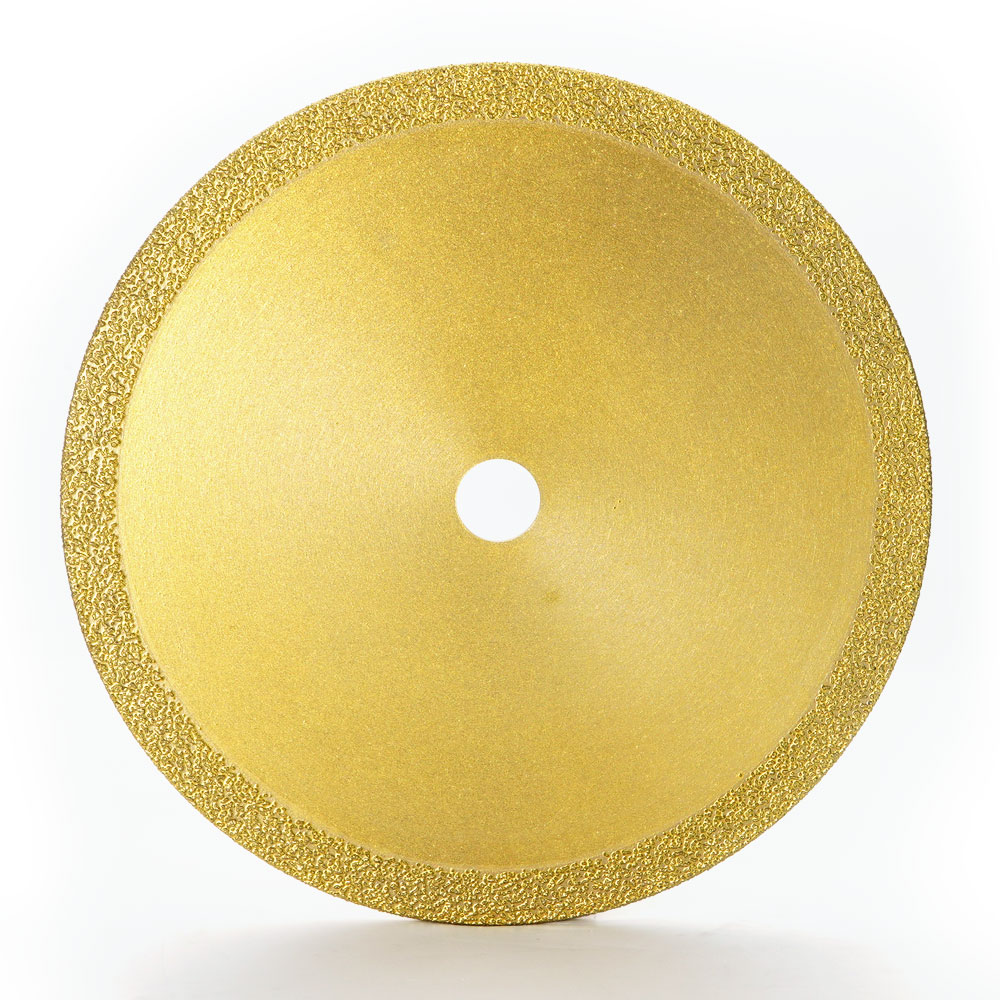

Brazed Diamond Cutting Wheel

Brazed diamond cutting wheels are tools used for cutting materials and are known for their high processing efficiency rate. This cutting wheel is not just ideal for complex surface machining but its unique production process which is called brazing is done by melting or flowing a certain filler metal on a lower melting point. The cutting wheels and abrasive discs of this product made up the whole production process in a much smoother and faster way. It also ensures a fast production process by grinding at a rapid rate. No need to worry about its body because this tool has a longer lifespan than other types of cutting wheels.

These brazed bond diamond wheels and discs are tremendous in applications and are suitable for marble, glass, ceramic, concrete, vitrified brick metal castings, blended materials, and other wider range of processing fields. What makes it essential in various industrial fields for work production is its wear resistance, compactness, and metallurgical features.

Features of Brazed diamond cutting wheel

- High-quality features. This tool is made with high-quality diamond grains which provides fire-resistant, excellent durability, and reliability on various materials like glass, ceramic, and stone.

- Suitability on various conditions. Working on a dry or wet condition is not a problem because of its flexibility and suitability feature.

- Durability and control. It can ensure longer life service compared to resin grinders with its durability feature. It is also pollution-free and can minimizes noise disturbance.

Detailed Description of Brazed Diamond Cutting Wheel

This diamond cutting wheel is made up of new brazing technology where the cutting discs have about 70% exposure to diamond particles. This is what makes it super aggressive on various hard materials. To know more about its components, applications, and benefits, here’s a brief description.

- The brazed diamond cutting wheel is composed of bare diamond particles which is a key factor in cutting various hard and rough materials.

- This tool is very much applicable in firefighting situations around the world especially when there is a need for a quickly forced entry into the buildings.

- This tool is super light and can easily be carried anywhere. This is what makes it very easy to control especially when you are cutting any workpiece. It is so stable that it has fewer chances of damaging the workpiece or material to be cut.

- This cutting wheel has is a cutter tool with multi-functions and purposes. It definitely works in both dry and wet environments, which is an advantage for the operator since working in any season will not be a problem. However, for safety reasons, it is advisable to use water or any cooling lubricant to lessen the heat that it generates during the work process.

- Compared to other traditional polishing discs, this tool is 40 times more durable and provides a longer life service. This is what makes it a good investment for future utilization.

- The blades of the cutting wheel have 100% sharpness and are very wear-resistant. With its high diamond density, you can ensure that the particles won’t fall off that easily. The blades are so strong that they can create a much smoother incision into the material used.

- Another good thing about this tool is its thickness which makes the cutter stable, balanced, unbreakable, and controllable. You can consistently fix it into any angle grinder or marble/ wood cutting machine without leading to any problems.

- This tool is very safe and eco-friendly as it reduces dust residue and bad odors that are harmful to those around the work area. You can assure that there will be no wasted because of its continuous rim shape.

More other customized cutting wheels are available, contact us.