Diamond and CBN cut off wheels are used for different material cutting and slotting usage, usually material like glass, ceramic, stone, carbide use diamond cutting wheel and CBN cutting wheel suit for material similar to steel.

Diamond cut off wheels: mainly used for slotting and cutting of ceramics, crystal, quarter,GMA, carbide, magnetic materials, electrical light wave glass tube and optical glass.

CBN cutting wheels: mainly used for slotting and cutting off tool steel, mold steel, bear steel, heat resistance steel, stainless steel, and cast iron.

Main industries applied:

1, Tungsten steel rod, a drill bit (bar sectional

cutting), PCB board micro-drill bit, die tip, electrode rod, Gong knife, the shuttle of textile industry, machine tool journal, machine tool axis, etc.

2, Optical glass, including camera lens, microscope lens.

Magnifier lenses, telescope lenses, spectacle lenses, etc.

3, Valve rods in automotive engines

4, For superfine sharpening stone dry slicing

5, For Magnetic Material Processing

6, For Cutting Slots of Brake Pads

7, For Circuit board

8, for sapphire processing

Cutting wheels of different types:

Cut off wheels’ application:

Metal Bond Cutting off wheel

Short Description:

The metal bond cutting wheel is a perfect abrasive tool for cutting. This tool is divided into two types; metal bond diamond cutting wheel and metal bond CBN cutting wheel. The metal bond diamond cutting wheel is a type that focuses on cutting hard materials for wear-resistant and short-chipping processes on various materials like glass, ceramics, carbide, ferrite, quartz, graphite, and semiconductor materials. On the other hand, metal bond CBN cutting wheel is applied on various materials that are mostly composed of affinity for carbon just like the iron-based alloys.

Features:

1) Fast Cutting, improve cutting effeciency

2) Free of chipping, Excellent cutting surfaces and edges

3) High Precise Cutting and grooving, High accurancy.

4) Smooth cutting, no clipping of the blades

5) Much longer life than tradtional abrasive cutting wheels.

Applications of Metal Bond Cutting Wheels

Since metal bond cutting wheels are highly durable and have hard-wearing qualities, various industries are fond of applying these tools especially on the glass, fine ceramics, semi-conductors packaging, hard metal, grinding materials, magnetic materials, electronic components, and other industries.

When it comes to applications, metal bond cutting wheels can be categorized into two: metal bond diamond cutting wheels and metal bond CBN cutting wheels. These two categories are used depending on the specific cutting applications such as deep cutting, glass cutting, wet or dry cutting, cut-off, and many more.

Note: There are several outer diameters for metal bond diamond and CBN cutting wheels specifically 3″, 4″, 5″, 6”, 7″, 8″, 10″, and 12″. The thickness of the wheel may depend on the client’s requirement.

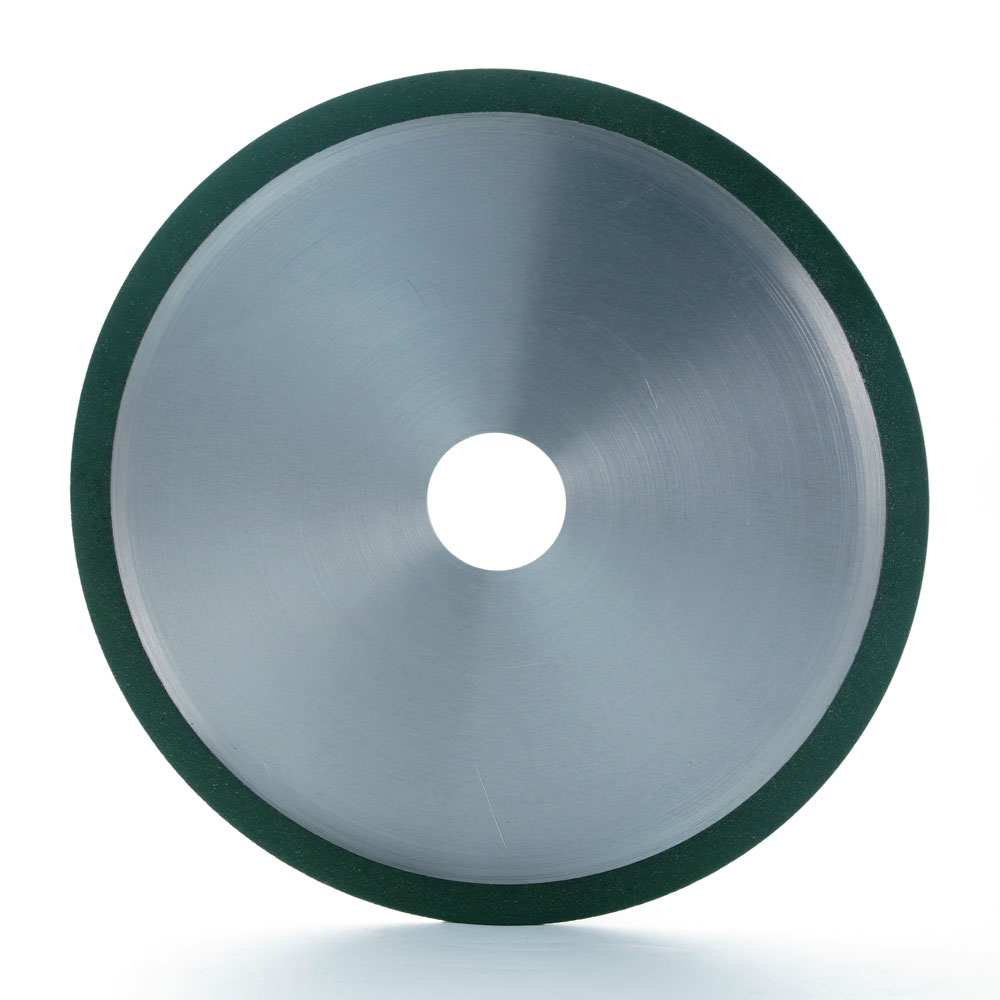

Resin Bond Cut off Wheels

These cutting wheels are very ideal for standard cutting wheels because it meets several cutting requirements for potential buyers. Among the existing bond cutting wheels, this tool is the most versatile for those who have expertise in cutting and grinding wheels.

Resin bond cutting wheels are built by expert engineering individuals in accordance with a specific cutting requirement. This tool comes with several benefits like self-sharpening abilities and high cutting efficiency features. It also has an excellent degree of elasticity which enhances the low in-feed forces. Due to this, this tool can ensure a smooth cutting operation which is applied by its superior performance and finishes.

Furthermore, like any other cutting wheel, it also has its heat resistance and wears resistance feature. These are very essential factors to improve the performance of the tool and extend its life service.

Aside from that, resin bond cutting wheels can be applied for dry and wet cutting operations in accordance with the used material, application, and requirements. This tool is highly recommendable because of its high cutting precision on various materials such as tungsten carbide, Inconel, stainless steel, high-speed steel, PCD & PCBN, and ceramics.

More customized Cutting Wheels are available, contact us.